Insights and updates: The future of ACONEXT

The town hall began with a series of exciting presentations that provided a comprehensive overview of the current developments and strategic goals of ACONEXT and the “Digital Future” division. Particularly highlights were:

- A successful close of 2023

- Continuation of our growth trajectory: We are particularly proud of our strong focus on Porsche, which continues to shape our growth strategy.

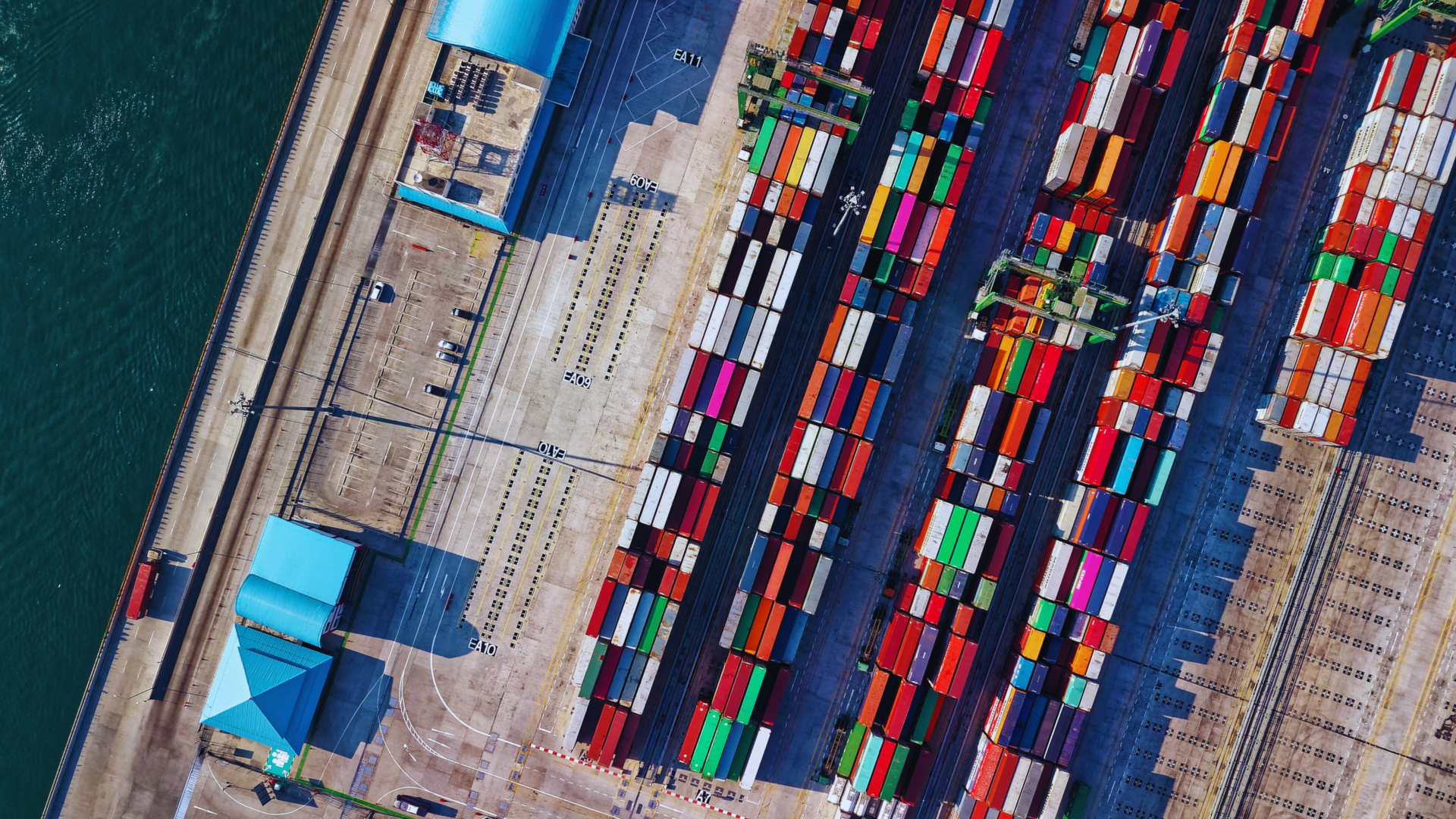

- New department: The establishment of the “Digital Supply Chain Management” department under the direction of Jan Herker, representing an important expansion of our expertise. More information can be found here.

- Plato project: A major milestone was reached, underlining our ability to manage complex projects.

HR and employer branding initiatives: Putting people first

Our HR team presented important innovations that strengthen the focus on personnel development:

- Job profiles and strategic portfolio: We are currently working intensively on developing new job profiles that meet our strategic objectives.

- New ACONEXT website: With the launch of our new website, including a subordinate career page, we are taking a major step forward in our digital presence and attractiveness as an employer.

- LinkedIn corporate influencers: We are increasing our visibility and networking through the planned promotion of ACONEXT corporate influencers on LinkedIn as well as weekly job highlights and insights into our day-to-day work.

Service portfolio: Leading in technology and innovation

Our comprehensive service portfolio was presented, underlining the breadth of our expertise and technological solutions:

- Top technologies: Digital Twins, Artificial Intelligence, Immersive Experiences (AR/XR), Hyper Automation, Cloud & Data.

- IT Consulting: IT/Mgmt strategy, architecture consulting, requirement management, method development.

- IT/cybersecurity: PDM / PLM / ERP / CAx, SAP consulting, testing, training.

Project presentations: Innovation in action

Our department heads and their teams presented impressive projects that illustrate our innovative strength and technological leadership:

- Digital Diagnostics: Progress on the XENTRY project at Daimler Truck.

- Digital after sales: Development of our HOT/Topas services at MBAG.

- Digital Innovation: Transition project at Daimler Truck.

- Digital Engineering: Start of our team in the Daimler Truck project Platon.

- Digital Supply: Development of our SCM Services

Expert ownership: Achievements and future goals

Our expert speakers played a central role at the event. We were able to celebrate the successes of the past year and clearly define our future goals:

- Community building: Building a strong specialist community and hosting workshops and training sessions.

- Professionalization: Further development of specialist topics and requirements for our job profiles.

- Successful projects: Requests from Daimler Truck AG for training and support, as well as the development of chatbots with GPT technology.

Interactive quiz and social get-together

At the end of the Townhall, an entertaining quiz was carried out to test and strengthen the knowledge and cooperation of the participants. While enjoying food and drink, our colleagues were able to exchange and develop new ideas in a relaxed atmosphere.

Conclusion: Together into the future

The “Digital Future” division town hall was a great success and once again underlined our culture of innovation and collaboration. We are on the right track and look forward to shaping the digital future together.

Many thanks to everyone who contributed to the realization of this successful event.

We are already looking forward to the next town hall and the exciting projects that we will carry out together.

Our engineers enthusiastically and creatively embrace the revolutionary challenges faced by the world of commercial vehicles. The focus is particularly on electrification, driven by a growing awareness of environmental sustainability. ACONEXT is pioneering the development of quieter and more environmentally friendly alternatives to diesel engines.

A key element for the future of commercial vehicle design is the integration of autonomous driving systems. Autonomous vehicles have the potential to increase safety and efficiency in freight transport by minimizing human errors and optimizing traffic. The connectivity of vehicles with infrastructure and each other can lead to intelligent traffic management by utilizing real-time data to optimize routes and avoid congestion.

The construction of mechanical components also faces demanding tasks. Lightweight construction increases energy efficiency, with materials such as carbon fiber, aluminum alloys, and composites playing a crucial role. Flexible design allows commercial vehicles to be adapted for various purposes and types of cargo. Modular designs enable the type of vehicle to be changed according to needs, whether for freight transport, waste disposal, or other purposes.

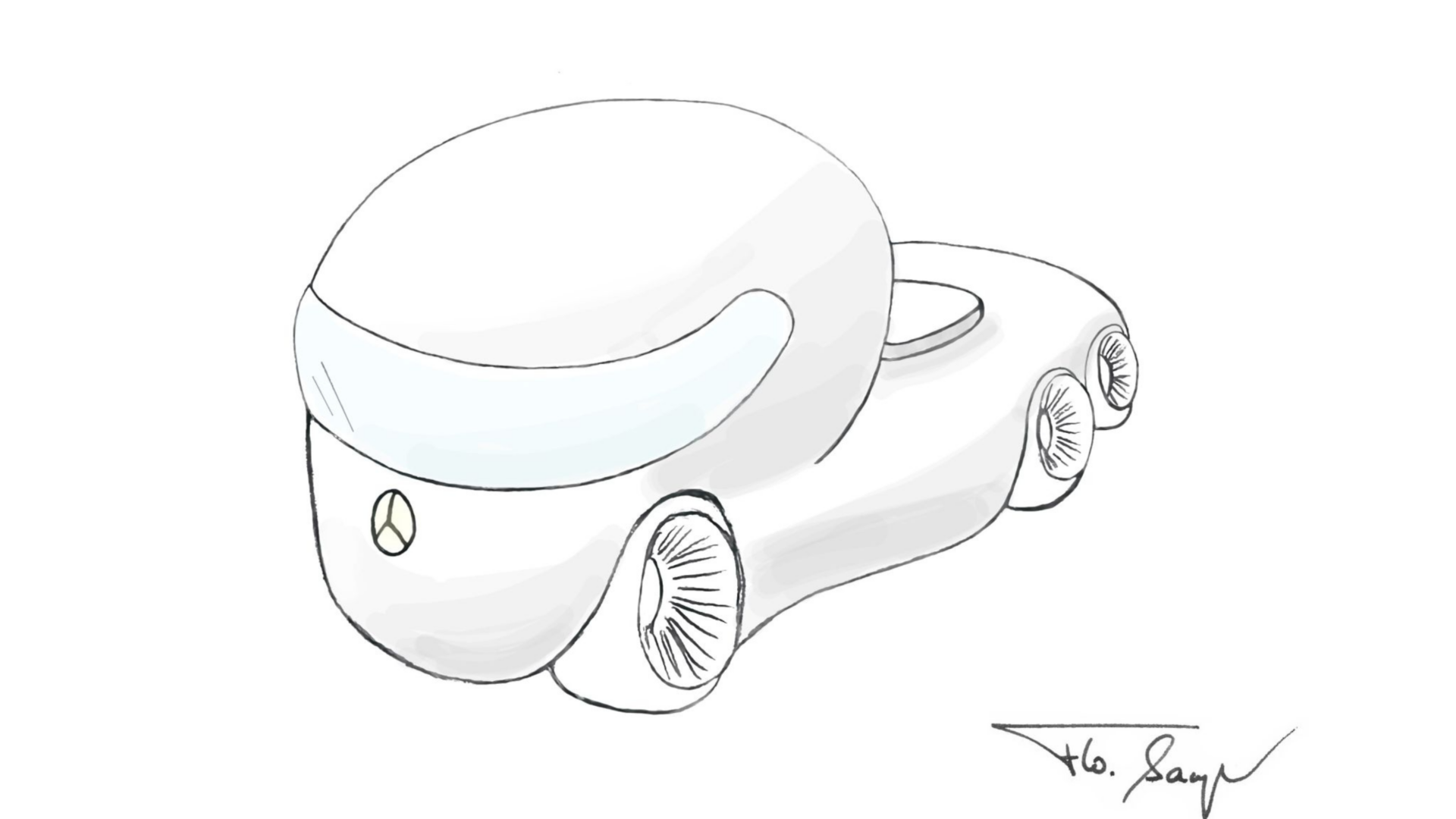

An essential factor for efficiency improvement is aerodynamics. Curved and optimized shapes reduce air resistance, thereby reducing energy consumption and increasing range. The enthusiasm of ACONEXT’s developers is reflected in their strong identification with renowned clients in the Swabian capital. This includes the Daimler Truck AG, with whom they are working on various aspects of the new generation of electric trucks. An outstanding example is Florian, a creative mind at ACONEXT, who not only works on important components but also has a passion for design. A glimpse into his vision provides insight into how the next generation of Daimler Trucks could be shaped.

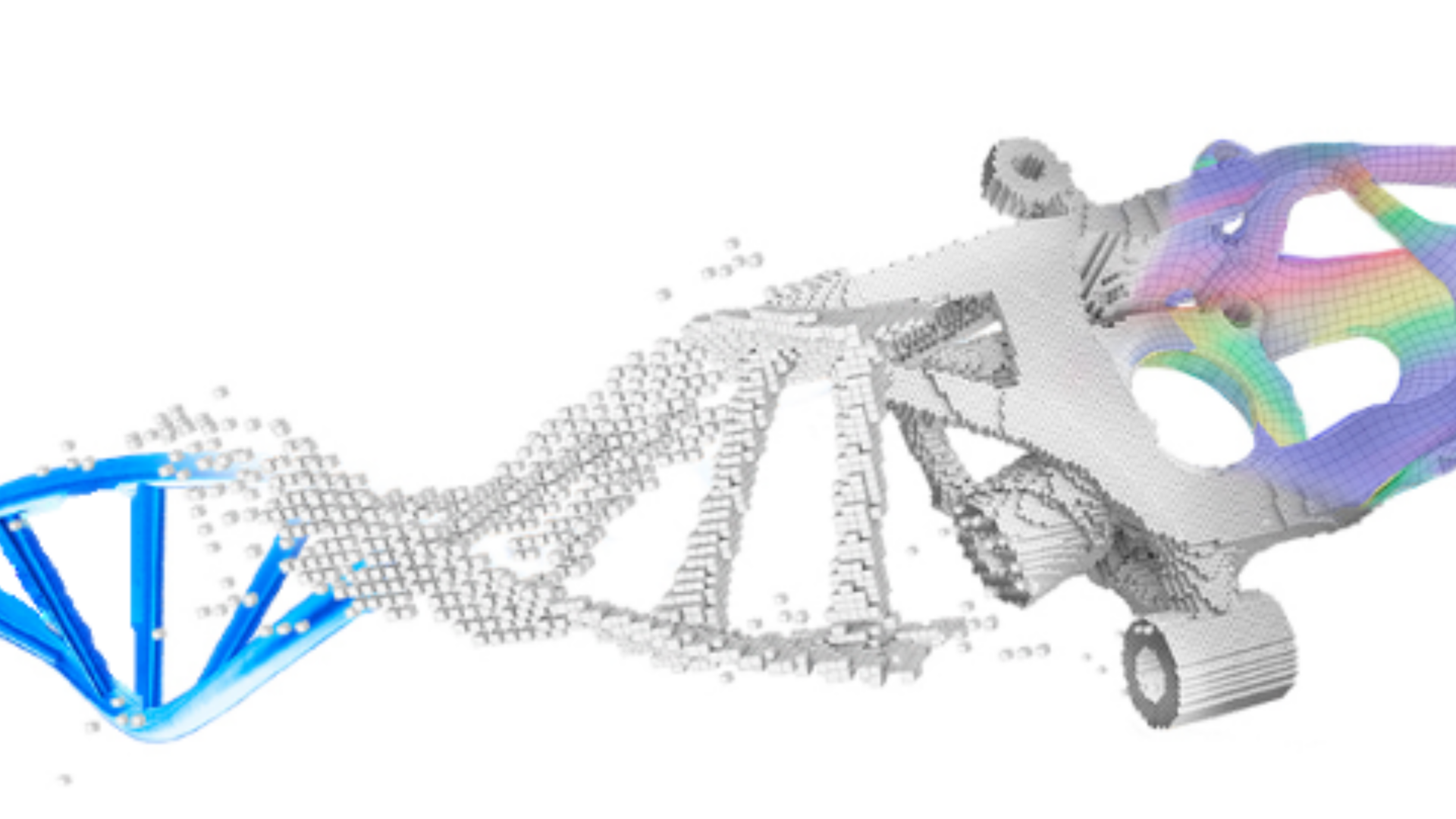

In a time when automotive engineering faces diverse challenges, low-code, as a groundbreaking technology, provides an answer to linear development processes, time-consuming iterations, and fragmented team collaboration. The tasks engineers face are complex and demanding. Traditional development processes, characterized by linear workflows and time-consuming iterations, impede progress. At ACONEXT, we have recognized that the solution to these challenges lies in low-code automation.

The manual effort, which takes up a significant portion of working hours, complicates coping with skilled labor shortages, shortened development cycles, and product diversification. This is precisely where low-code comes in, providing engineers with a unified visual language through intuitive drag-and-drop editors, helping to overcome common challenges more quickly.

The low-code technology we are already using today is nothing short of a revolutionary approach. Our engineers benefit from an open platform that seamlessly connects all tools in the product development process. Automating manual steps, integrating expert knowledge, and optimizing routines enable our teams and customers to focus on the essentials and develop creative solutions.

By implementing low code at ACONEXT, we have reduced development time for processes or components by up to 75%. Low-code workflows replicate recurring processes and can be effortlessly adapted to various use cases. This provides more time and space for creative solutions and strategic innovations, representing a clearly measurable increase in efficiency.

Our goal at ACONEXT is to consistently pursue the path of efficiency improvement and expand the benefits of low-code to increasingly complex components. With low-code, we see the opportunity to actively shape the future of engineering for our customers and thereby open up new horizons.

Would you like to learn more about how we use low-code at ACONEXT to increase your efficiency? Contact us to discuss innovative solutions in the context of digital development and master your automotive projects together.

A detailed look at the versatility of CFD reveals how it drives the development of innovative products and the optimization of complex processes in the automotive sector. The roots of CFD date back to the 1940s when researchers began developing mathematical models to simulate the behavior of liquids and gases. In today’s time, CFD enables advanced simulations specifically tailored to the requirements of the automotive industry. Through the precise application of CFD simulations, engineers can solve complex flow problems and find innovative solutions for vehicle designs and efficiency.

Whether in the design of autonomous vehicles or the optimization of aerodynamic properties, CFD provides precise insights into flow mechanics that are relevant to the automotive and aerospace sectors. ACONEXT harnesses this technology to deliver advanced solutions for vehicle and component development. Simulation allows testing components under realistic conditions while avoiding costly field measurements.

“Turbulent flows mean chaos, unlike our projects, which are characterized by systematic approaches and structured development processes.”

— Dirk Heinrich, Head of Numerical Fluid Mechanics | CFD

The cost-effectiveness of CFD is particularly evident in the examination of physical quantities in hard-to-reach areas. Through accurate CFD analyses, we can assist our customers in making informed decisions to maximize the efficiency, safety, and performance of their vehicles. This advanced technology opens new dimensions for designing efficient, safe, and powerful vehicles.

ACONEXT is an experienced partner for innovative engineering services within vehicle development. Our CFD experts not only provide technical support but also give your vehicle projects the crucial boost needed for significant transformations. The path to top-notch vehicle innovations begins right here – explore the possibilities of CFD simulations and shape the future of automotive technology together with ACONEXT.

Whether you are involved in the development of electric vehicles, internal combustion engines, or other vehicle technologies – let’s collaborate to find innovative solutions for your projects. Contact our expert team for an initial discussion on topics related to flow simulation and many other simulation services at: simulation@aconext.de